Passivation is a chemical process that improves the ability of stainless steel and other alloys to avoid corrosion. Metals will rust when exposed to the environment, forming the skin or seal layer if not protected by paint or powder coating. Most passive films, also known as passive oxide layers, are composed of oxides, which are metal and oxygen compounds.

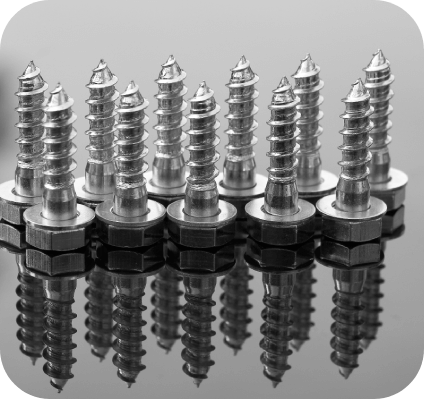

Stainless steel is cleaned and given a corrosion-resistant coating through passivation. Our passivation process lessens the likelihood that an item made of stainless steel will get compromised by environmental elements like water or oxidation. Rusting and other types of corrosion can eventually lead to disastrous outcomes on stainless steel surfaces.

Parts made of stainless steel can chemically be treated to give passivation, which offers resistance to rusting, oxidation and mild chemical assault. Free iron that can be produced during finishing operations like milling, lapping, cutting, polishing, etc., is removed from the surface of the parts by the passivation process. By returning the resistive qualities of machined components to the state of their particular alloy’s raw material, the passivation process eliminates the danger of corrosive contamination.

As a result, the method is used by a variety of industries, including those in the automotive, aircraft, communications, machining, electronics, medical, and military.

Advantages:

- Following machining, residual impurities are removed.

- Increased resistance to corrosion

- Less danger of contamination during manufacture.

- Enhanced performance of the component.

For a variety of sectors, FMC offers passivation and cleaning services. In addition to commercial and AAA (Acid-Alkaline-Acid) passivation in nitric and citric acid, our services include precision and medical-grade cleaning passivation.

We provide stainless steel passivation and corrosion prevention services that speed up and enhance the material’s passive oxide layer’s effects, increasing its resilience. The passive layer of film, which offers resistance to corrosion, can build more quickly with the help of our unique nitric acid/sodium dichromate solution, which also removes free iron and other pollutants from the surface without harming the material itself.

Standards Followed In FMC

ASTM A967 – Chemical Passivation Treatments for stainless steel parts